What disc. brake conversion for a 71' Cuda is a good choice for non power and good not hard pedal feel ? Same as factory quality ,street setup . We wanted power disc but not enough vacuum, no vac. pump. no chevy calipers .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

71" cuda Disc .which brake conversion ?

- Thread starter Dustu

- Start date

bc3j

Well-Known Member

I used all factory Mopar parts following the Disc-O-Tech article with a few exceptions for manual brakes. I used the combination valve used after 1-1-1970 with the metering valve. Rotors are 11.75” (need 15” wheels), Dr. Diff’s aluminum 1.031 master (not excessive pedal force), semi metallic pads. My car feels like my Acura RDX pedal does. Car stops great, no rear wheel lockup. I found that out in an unexpected panic stop on the Interstate with rapidly slowly traffic. That stop definitely built up my confidence in the car’s abilities to stop around modern stuff. I also had experimented with and without the metering valve. Too much nose dive without it. With the metering valve very little nose dive and more weight on the rear as I my unplanned panic stop proved to me.

I found all Mopar sourced parts work well together. There are a lot of available brake kit options.

The master cylinder bore size is the wildcard, it’s a subjective feel. After increasing my master cylinder to 1.031, I was surprised that the pedal feel was virtually the same with half the travel, slightly more pressure. Extremely happy with my setup and stopping power.

I found all Mopar sourced parts work well together. There are a lot of available brake kit options.

The master cylinder bore size is the wildcard, it’s a subjective feel. After increasing my master cylinder to 1.031, I was surprised that the pedal feel was virtually the same with half the travel, slightly more pressure. Extremely happy with my setup and stopping power.

Last edited:

rogue

Well-Known Member

- Joined

- May 21, 2013

- Messages

- 228

- Reaction score

- 56

i have wilwood on my challenger and cuda

Old B5

Well-Known Member

I used The Right Stuff kit. I would not recommend them. Terrible customer service, not a good design and cheaply made. Spend a little more and get a quality system from one of the better known brands.

On your e body conversion did you have power drums already ? So you used the combo factory valve, was it for a non power disc.. car ? I see with metering valve ,have the part no s.? I have read that it was recommended to use a smaller dia. master cylinder ,7/8 ,15/16 maybe ? But yours sounds good . Did you have to do anything with the pedal to master cyl. ratio ?I used all factory Mopar parts following the Disc-O-Tech article with a few exceptions for manual brakes. I used the combination valve used after 1-1-1970 with the metering valve. Rotors are 11.75” (need 15” wheels), Dr. Diff’s aluminum 1.031 master (not excessive pedal force), semi metallic pads. My car feels like my Acura RDX pedal does. Car stops great, no rear wheel lockup. I found that out in an unexpected panic stop on the Interstate with rapidly slowly traffic. That stop definitely built up my confidence in the car’s abilities to stop around modern stuff. I also had experimented with and without the metering valve. Too much nose dive without it. With the metering valve very little nose dive and more weight on the rear as I my unplanned panic stop proved to me.

I found all Mopar sourced parts work well together. There are a lot of available brake kit options.

The master cylinder bore size is the wildcard, it’s a subjective feel. After increasing my master cylinder to 1.031, I was surprised that the pedal feel was virtually the same with half the travel, slightly more pressure. Extremely happy with my setup and stopping power.

Chryco Psycho

Well-Known Member

I have done many of the 11.75 Cordoba disc swaps , hydroboost is a better option with low vacuum if you want power & have power steering which my cars do not .

not doing powerI have done many of the 11.75 Cordoba disc swaps , hydroboost is a better option with low vacuum if you want power & have power steering which my cars do not .

moparleo

Well-Known Member

- Joined

- Oct 17, 2011

- Messages

- 7,105

- Reaction score

- 1,891

Ditto on the Disc-o-tech by Ehrenberg. Basically 73 and up factory components.

Can't go wrong. Easy to get replacement parts and good braking for normal driving.

Be sure to do a good brake fluid flush every couple of years to get the moisture out of the fluid.

Can't go wrong. Easy to get replacement parts and good braking for normal driving.

Be sure to do a good brake fluid flush every couple of years to get the moisture out of the fluid.

DISC-O-TECH: Stop on a dime from Mopar Action and Rick Ehrenberg

DISC-O-TECH: Stop on a dime from Mopar Action and Rick Ehrenberg

www.allpar.com

Chryco Psycho

Well-Known Member

Yes manual 11.75 cordoba disc no assist

bc3j

Well-Known Member

My car was manual. Since the factory didn’t offer a manual disc brake car in ‘70, I used the factory system because it was engineered for disc brakes. Also stuck with all Mopar sourced parts because I lean towards the factory parts which work well together. The brake pedal is the same for all cars, except the power brake cars used the linkage assembly. My stock brake pedal is a hair over 7:1.On your e body conversion did you have power drums already ? So you used the combo factory valve, was it for a non power disc.. car ? I see with metering valve ,have the part no s.? I have read that it was recommended to use a smaller dia. master cylinder ,7/8 ,15/16 maybe ? But yours sounds good . Did you have to do anything with the pedal to master cyl. ratio ?

The master cylinder bore size is the wildcard. I went with 1.031 MC because the pedal travel with the 15/16 MC was uncomfortably long for my comfort level. Also with a psi gage on the front caliper, I had to put a lot of leg on the pedal, was nearly touching the floor and was still just under 1200 psi. Not a confidence builder for me. So I changed to 1.031 and never looked back. It came down to my comfort level and the ability to comfortably stop the car in all situations. That’s the MC that worked for me, not excessive pedal force, and the car stops quite well. My Acura RDX also has some variable pedal force component depending on the conditions required to stop the car at any given moment. That was my overall goal. It is a total package considering the entire braking system, including the friction coefficient of the brake pads.

Upside is the MC is easy to change and I have a pressure bleeder and tool C-4121 to hold the metering valve open. I’ve changed many MCs, some because they were Chinese junk and leaked, others searching for my comfort zone. So changing them was only a slight inconvenience.

Last edited:

pschlosser

Well-Known Member

... I used the factory system because it was engineered for disc brakes. Also stuck with all Mopar sourced parts because I lean towards the factory parts which work well together. ...

When making a conversion, brakes, engine, just about anything, using correct OEM parts is like a pleasant dream compared to the frustration and patience (required) to resolve issues that sometimes come up when non-oem/other parts don't play well together.

On top of that, these cars are getting rarer and finding correct solutions (compared to speculative ones) can add to frustration.

Last edited:

Do you remember what M C was for exactly ? Or did you just use the power disc. m c for 70 ' ebody and a 70 e body model combo and metering valve ? Correct ?My car was manual. Since the factory didn’t offer a manual disc brake car in ‘70, I used the factory system because it was engineered for disc brakes. Also stuck with all Mopar sourced parts because I lean towards the factory parts which work well together. The brake pedal is the same for all cars, except the power brake cars used the linkage assembly. My stock brake pedal is a hair over 7:1.

The master cylinder bore size is the wildcard. I went with 1.031 MC because the pedal travel with the 15/16 MC was uncomfortably long for my comfort level. Also with a psi gage on the front caliper, I had to put a lot of leg on the pedal, was nearly touching the floor and was still just under 1200 psi. Not a confidence builder for me. So I changed to 1.031 and never looked back. It came down to my comfort level and the ability to comfortably stop the car in all situations. That’s the MC that worked for me, not excessive pedal force, and the car stops quite well. My Acura RDX also has some variable pedal force component depending on the conditions required to stop the car at any given moment. That was my overall goal. It is a total package considering the entire braking system, including the friction coefficient of the brake pads.

Upside is the MC is easy to change and I have a pressure bleeder and tool C-4121 to hold the metering valve open. I’ve changed many MCs, some because they where Chinese junk and leaked, others searching for my comfort zone. So changing them was only a slight inconvenience.

Challenger RTA

Well-Known Member

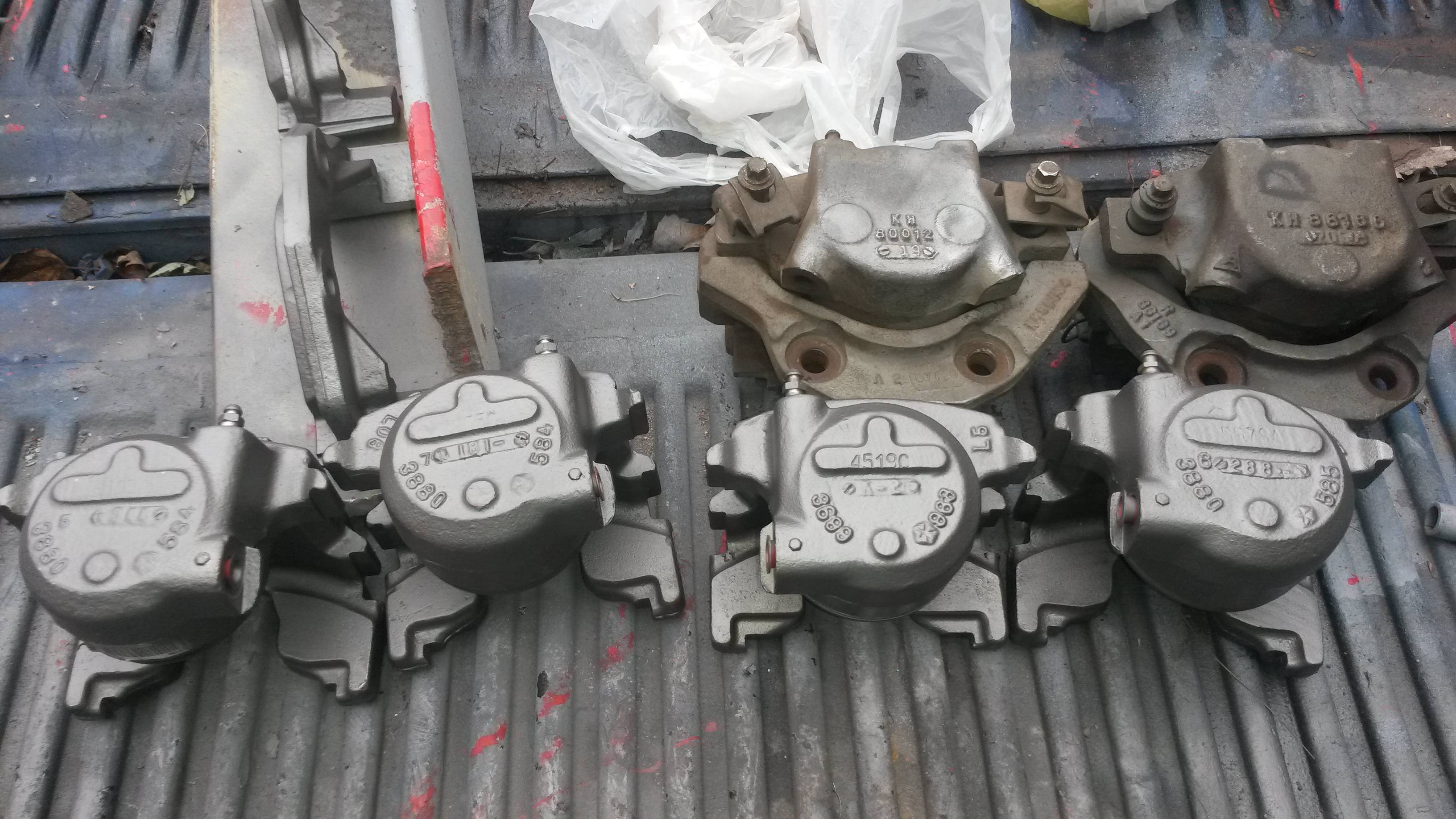

What some others are suggesting is what I put a while back.The pin type caliper where ok. But I was doing a lot of driving from base to home. It always felt like the passenger side was warmer and I though the caliper was hung up.had it apart a few times seemed ok.Way back when A mopar ship mate told me to check the pins. I did and one was bent.replaced it was ok. I think I put at the least 15k miles that year. Let me check the math. 275x2=550 round trip every other weekend or more. x 26=1,4300mile yep at a minimum. Pictures of parts below that are needed. Rotors dust shield brake hose too. [A body I think] can be bought new. calipers and sliders would have to be sourced used or rebuilt. pay no attention the the numbers on the the sliders The may be for the rear,check the numbers before you source. And a DR diff bushing if need be. 15" wheels needed. Much better then going why overboard.And their stock parts. Others here that have done the manual swap know better from trial and error. Mine are power. just may experience. Good luck. OH yeah do the 11/16 weenies.

Last edited:

bc3j

Well-Known Member

I used this combination valve. The MC was from Dr. Diff. It was the aluminum 1.031 MC. It had the Mopar 1/2-20 and 9/16-20 ports. The pic was from Dr Diff’s website. He has both the combination valves and the MC. He is a great guy to deal with. He also has the 15/16” MC in the aluminum style. Both MCs have the recessed groove to retain the manual brake pushrod.Do you remember what M C was for exactly ? Or did you just use the power disc. m c for 70 ' ebody and a 70 e body model combo and metering valve ? Correct ?

Similar threads

- Locked

- Replies

- 0

- Views

- 594