moparmaniac10

Well-Known Member

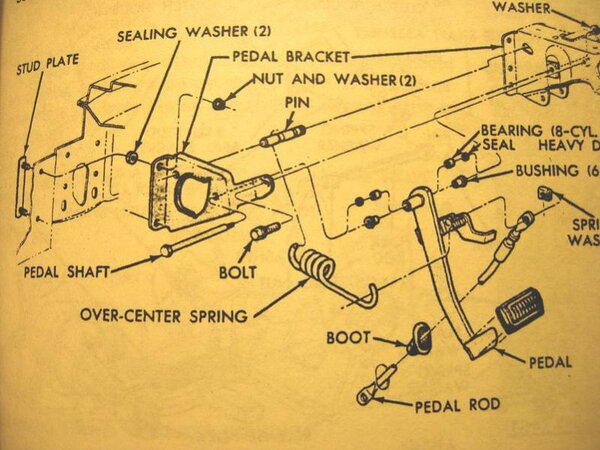

So I took my whole pedal assembly out of my 71 challenger, blasted and painted it, bought all new bushings and everything. I got the whole pedal assembly put back in, except I cannot get the huge spring back on. I hear there is a really easy trick to getting it back on, but I don't know what it is. Please Let me know, if you know. I'm tired of fighting with it.