By no means I am not an expert. Maybe They have a special grind cam,I don't think so.I’ve read about camshafts that some cam companies grind advance into the camshaft. How does the cam company grind advance into the cam?

Everyone tends to look at the intake and exhaust lobes as separate movements within the engine’s operation, but what we really need to do is look at the entire function of the

camshaft and how all the different events coincide. It is true that many camshafts are designed with advance built into them. The majority of these cams are intended for street use. Here’s how it all comes together.

The cam companies know that when it comes to choosing a camshaft, many enthusiasts tend to suffer from the “More is Better” theory of engine performance. The common approach is that if some additional lift and duration is good, then more is better. So instead of choosing a typical 220 degrees at 0.050-inch tappet lift cam for a mild street engine, many enthusiasts – especially first-time buyers – will upgrade their selection and go with maybe a 236 or 242 degrees at 0.050 cam instead because a buddy told them that’s what they needed.

The unfortunate result is that these longer duration camshafts tend to reduce low-speed torque in favor of top-end power. The camshaft companies know this. One way to improve the low-speed torque on a camshaft with too much duration is to advance the intake lobe in relation to the exhaust. Advancing just the intake lobe opens and closes the intake valve sooner which is one way to help improve the low-speed torque.

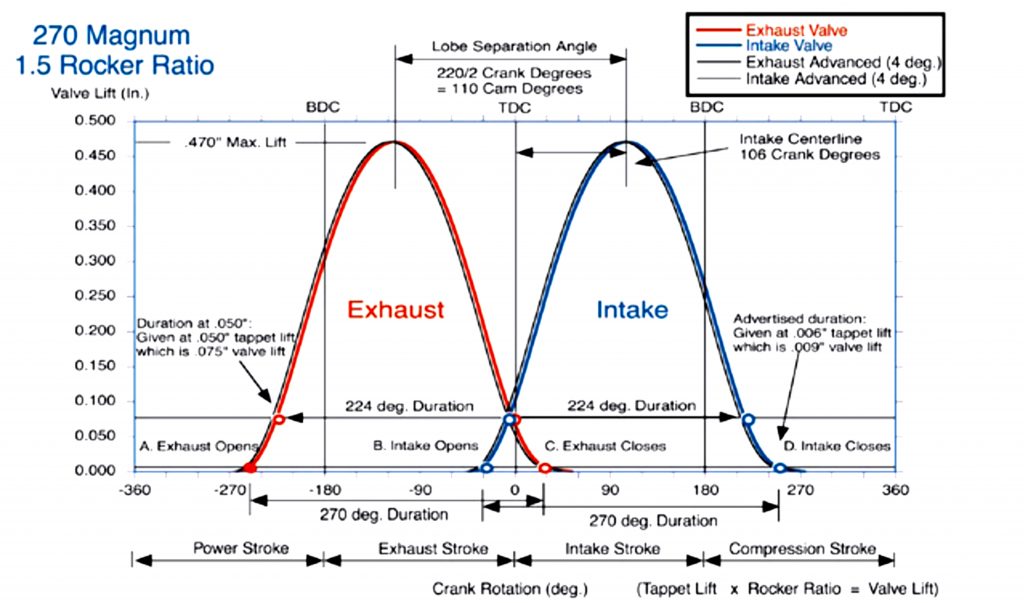

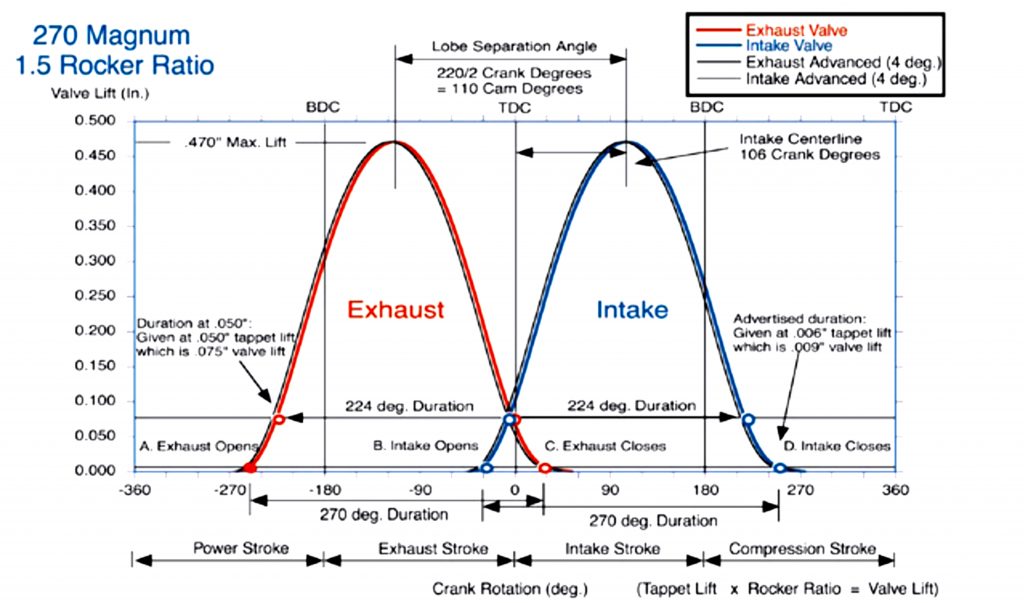

We’ve included a

Comp Cams illustration of the intake and exhaust lobe lift and duration curves on a simple diagram that makes all this a little easier to understand. If all the cam company did was advance the intake lobe position on the cam, this would also decrease the lobe separation angle and increase the number of degrees of overlap.

You can learn quite a bit just by studying this Comp Cams illustration of cam timing. Advancing either lobe would move it to the left while retarding would move either lobe to the right on this diagram. So you can see how advancing just the intake lobe (the one on the right) would change the intake centerline but also increase overlap.

Overlap is the amount of time, in degrees, when both the exhaust and intake valves are open. You can see this represented by the small triangle shaped area in the center bottom of the two curves. Overlap was called the “Fifth Cycle” by Ed Iskenderian back in the 1960’s when engine builders were first discovering how much mid-range power can be improved by adding overlap. The downside to increasing overlap is that it tends to hurt idle vacuum. This is also what creates the classic lumpy, uneven idle that everybody wants so their engine sounds like a killer Pro Stock drag race powerplant.

Bu too much overlap can really hurt the off-idle performance so the cam companies typically advance the intake lobe and retard the exhaust lobe to maintain a decent lobe separation angle. For example, almost all Comp street cams use a 110-degree lobe separation angle.

There is a very easy way to tell if the camshaft has been advanced by the cam company when the cam was machined. Look at the cam timing card and compare the lobe separation angle (LSA) with the intake centerline number. If the numbers are the same, then the camshaft has not been advanced.

Let’s look at an example. This first example is a Comp cam we currently have in a 496 big block Chevy we built. It’s a

mechanical roller with 261 degrees duration at 0.050-inch tappet lift on the intake and 270 degrees on the exhaust with 0.734-/0.737-inch valve lift (PN 11-851-9). The intake centerline is listed on the cam card at 108 degrees and the LSA is also 108 degrees. In this case, the cam has been ground with no advance as the numbers are the same.

Now let’s evaluate a much milder Comp

hydraulic roller camshaft for an LS engine. This is PN 54-456-11 with 219 and 227 degrees of duration at 0.050-inch tappet lift with 0.607-/0.614-inch lift. When we look at the cam card, the intake centerline is listed at 107 degrees while the LSA is listed at 112 degrees. The numbers tell us the intake centerline has been advanced five degrees from 112 to 107 degrees after top dead center (ATDC).

As a simple exercise to put all this in perspective, there is an easy way to mathematically determine the lobe separation angle. This does not necessarily require measuring the camshaft’s intake and exhaust centerlines. But for right now, let’s say we have the numbers with the exhaust centerline at 112 degrees BTDC and the intake at 112 degrees ATDC. Simply add the two numbers together and divide by 2. The equation would be:

112 + 112 = 224 /2 = 112 degrees LSA.

In the case of the LS cam, we know the intake centerline is 107 degrees ATDC and the LSA is 112, so if the exhaust was the same number of degrees from TDC, that would put it at 107, but adding 107 + 107 = 214/2 = 107 and the cam cards indicates that the LSA is 112 degrees. That means that the exhaust centerline has advanced 10 degrees because the difference between the LSA and the intake centerline is 5 degrees. Placing the exhaust lobe centerline at 117 degrees puts the numbers in place:

117 + 107= 224 /2 = 112-degree LSA.

Now because we have so many Dual Over Head Camshaft (DOHC) engines in production today, let’s just take a second and discuss what the OE’s are doing for 21st century engines. Since a DOHC engine uses a separate intake and exhaust camshaft, this allows engineers to move the intake and exhaust lobes separately. So now with hydraulic adjusters, the ECU can move either cam separately to advance or retard the intake or exhaust. So for low=-speed driving, they advance the intake and retard the exhaust to maintain a sewing machine idle.

Then, somewhere in the midrange when the engine would really respond to lots of overlap, they begin to retard the exhaust to create more overlap. In reality, most of the DOHC engines only move the exhaust lobe for emission reasons. As an example, Fords Variable Cam Timing (VCT) engines only change one lobe while the Ti-VCT (Twin Independent Variable Cam Timing) moves both cams.

This is probably more than you wanted to know about camshaft positioning, but this might come in useful at some point. If nothing else, you can use it to dazzle your friends with you incredibly acute knowledge of camshafts and how they work. Or maybe not…

Here’s a breakdown of the advantages of advancing or retarding your cam timing:

Advance Cam Timing

- Begins Intake Event Sooner

- Opens Intake Valve Sooner

- Builds More Low-End Torque

- Decreases Piston-to-Valve Clearance

- Increases Piston-Exhaust Valve Clearance

Retard Cam Timing

- Delays Intake Closing Event

- Keeps Intake Valve Open Later

- Builds More High–RPM Power

- Increases Piston-to-Valve Clearance

- Decreases Piston-Exhaust Valve Clearance

I don't think that is the case in this situation 12 degrees?