Challenger RTA

Well-Known Member

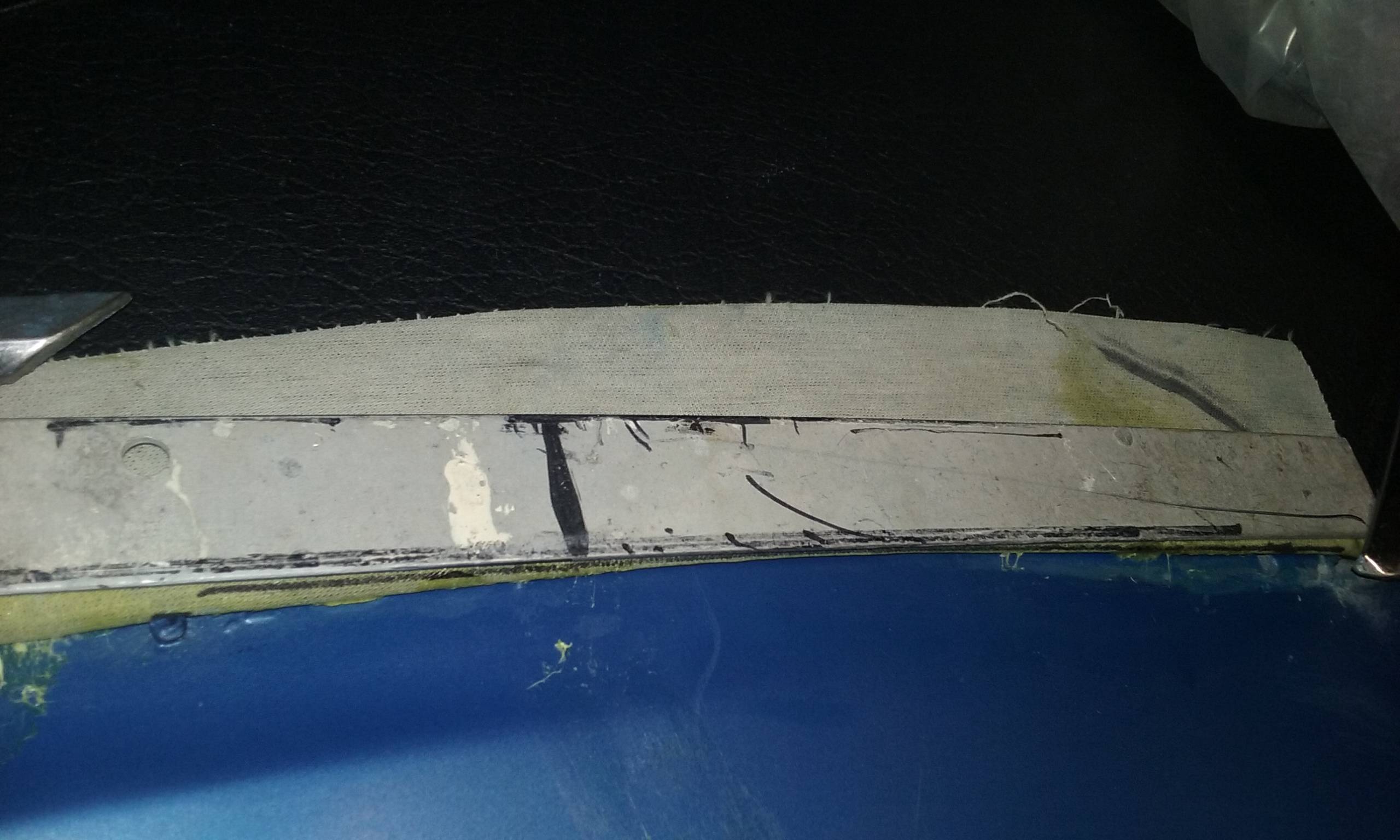

Had to wait for any suppler to get lokweld in stock and ship. 1st picture: completed area from seam to drip rail and continued along sail panel as doing seam area. 1-2" strips.continued down sail panel about 4" below top of rear window frame. Then pulled and glue seam to the bottom of window,from the seam to the window. 2nd picture: shows 95% of panel pulled an stretched by down and back. Had to pull forward also a little get folds out. stopped about an inch above trim so I can fold up and mark to cut. For the must part didn't go to bad. just clue an inch or two at a time. did no relief cut. rolled the drip rail.trim would not go over vinyl,to tight.

3rd picture: trimmed vinyl ti drip rail and installed. 4th picture: show how I was running the glue pattern straight back. 5th picture: shows mostly done. has folds present,but after trimmed they all pushed out. 6th picture: folded up and marked so the cut is just below the studs.mark it long to be sure you can cut it again! lay trim on to see if you enough. Here;s where BARRACUDA BUZZ would say " I F##K UP!!!" 7-8 Pictures: Every thing was going good,Right! Wrong! When first test fitting. placing top where it belonged. It seamed a hair short. it would barely make to the center molding studs on the Dutchman panel.But the trim would cover it with no problem and it did. When stated trimming around window to glue and was no problem.started on the Dutchman panel after window area was cut out. there was to much slack. WHO would of thunk after it being tight before it was cut.Now there is to much slack. About a 1/4" and no where for it to go! 9th picture: started in the middle glued and worked some slack to the sides,but not tight! I end up with a 1/8 fold on each side. Might try to steam out or it might shrink from the heat of the sun. 10th picture: Trim on there loose. 4-5 bubble from not being tight. gave glue a little longer to set up and pushed to top and bottom and gone.

Window trim:top were studs.Side 3 holes one each side,spaced from the bottom.1 1/2" 7 1/2" 12 1/2".

3rd picture: trimmed vinyl ti drip rail and installed. 4th picture: show how I was running the glue pattern straight back. 5th picture: shows mostly done. has folds present,but after trimmed they all pushed out. 6th picture: folded up and marked so the cut is just below the studs.mark it long to be sure you can cut it again! lay trim on to see if you enough. Here;s where BARRACUDA BUZZ would say " I F##K UP!!!" 7-8 Pictures: Every thing was going good,Right! Wrong! When first test fitting. placing top where it belonged. It seamed a hair short. it would barely make to the center molding studs on the Dutchman panel.But the trim would cover it with no problem and it did. When stated trimming around window to glue and was no problem.started on the Dutchman panel after window area was cut out. there was to much slack. WHO would of thunk after it being tight before it was cut.Now there is to much slack. About a 1/4" and no where for it to go! 9th picture: started in the middle glued and worked some slack to the sides,but not tight! I end up with a 1/8 fold on each side. Might try to steam out or it might shrink from the heat of the sun. 10th picture: Trim on there loose. 4-5 bubble from not being tight. gave glue a little longer to set up and pushed to top and bottom and gone.

Window trim:top were studs.Side 3 holes one each side,spaced from the bottom.1 1/2" 7 1/2" 12 1/2".

Last edited: