You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Daily Driver 71 Cuda 440+6 / Shaker / 4 speed / Dana 60

- Thread starter Craig J

- Start date

Cuda Hunter

Well-Known Member

Nothing wrong with that! Looks great!

gzig5

Well-Known Member

Who was the source for the frame rail/inner fender sub-assemblies?

I'm almost positive there wasn't an engineer involved in the welding decision. Probably the minimum someone thought would hold it together in order to save time and material.

I'm almost positive there wasn't an engineer involved in the welding decision. Probably the minimum someone thought would hold it together in order to save time and material.

Challenger RTA

Well-Known Member

It's surprising how strong a proper spot weld is. Usually the metal tears long before the weld gives away. more welded area the better. I seen the kit you have are thesis included? An other issue with welding body panels is treating all welded areas. both sides with a metal prep to prevent premature rust. Good job!

Craig J

Well-Known Member

Fit up is not going well…. I bolted the front pin location at 34” and the radiator mounting points at 28” but something is not right… the bottom of the radiator mount is not aligned correctly… I am reluctant to cut the drivers side but I can not see any other option.

Can anyone confirm that 28” is the right dimension for the radiator mounts?

Can anyone confirm that 28” is the right dimension for the radiator mounts?

Challenger RTA

Well-Known Member

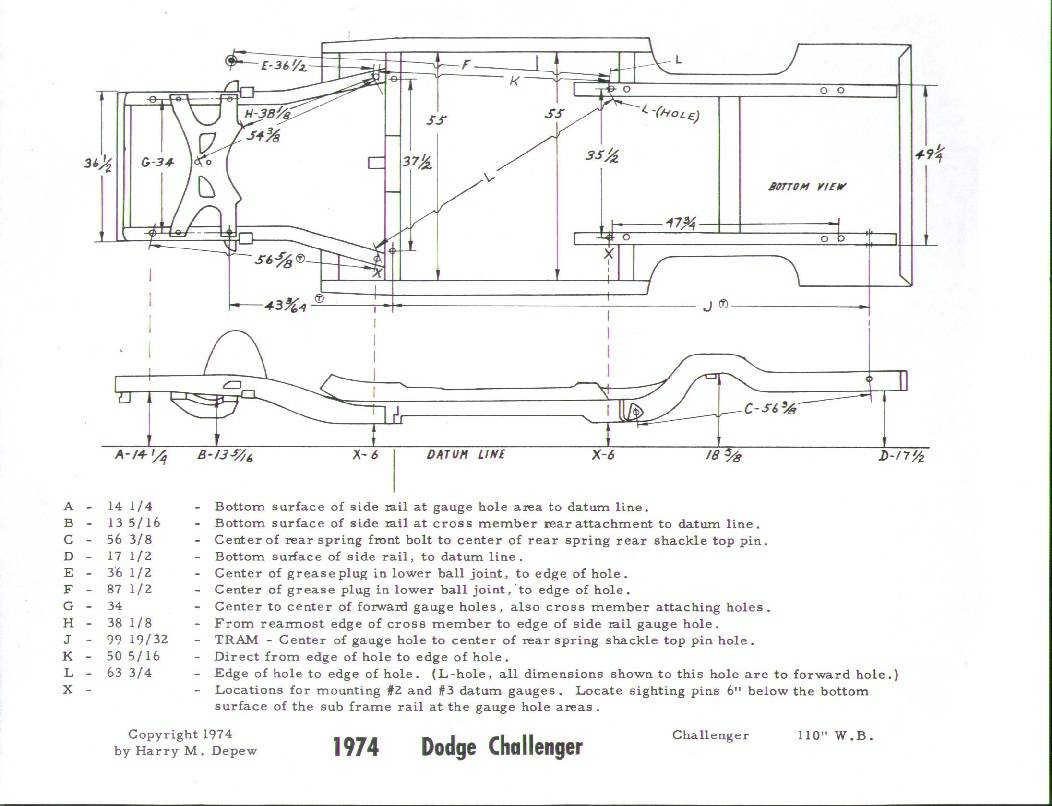

The measurements you have to use are below. Loosen K frame bolts. move front rails the measurements. G 34" H 38 1/8" 54 3/8" Yes 28" to center of top radiator bolts.give or take 1/16"

Last edited:

Craig J

Well-Known Member

G is 34

The problem is that the radiator opening is 1/2 wider at the top than the bottom.

The problem is that the radiator opening is 1/2 wider at the top than the bottom.

Challenger RTA

Well-Known Member

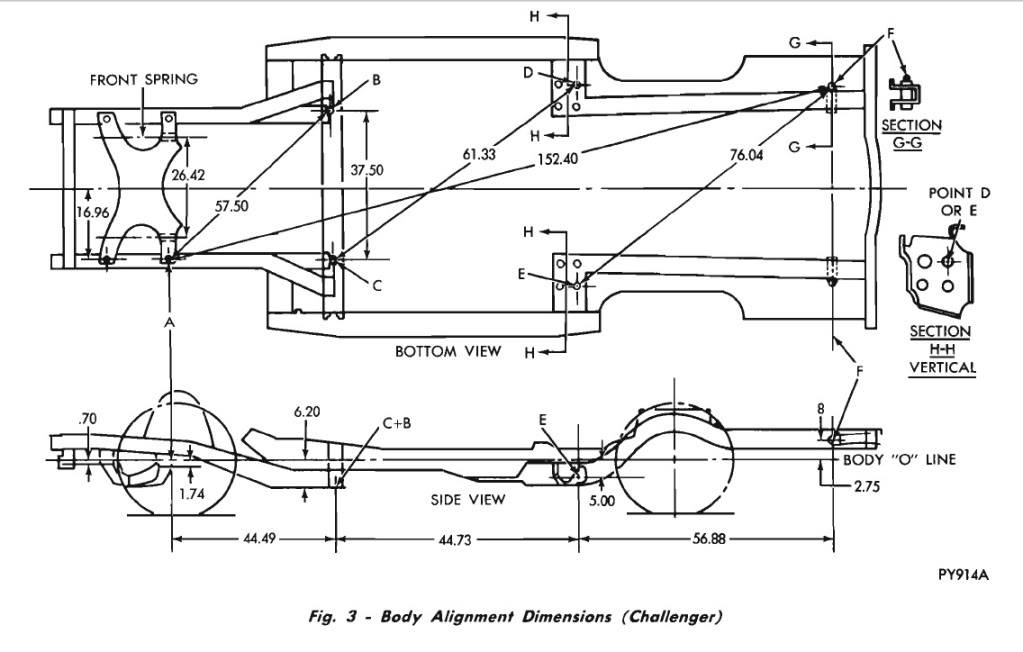

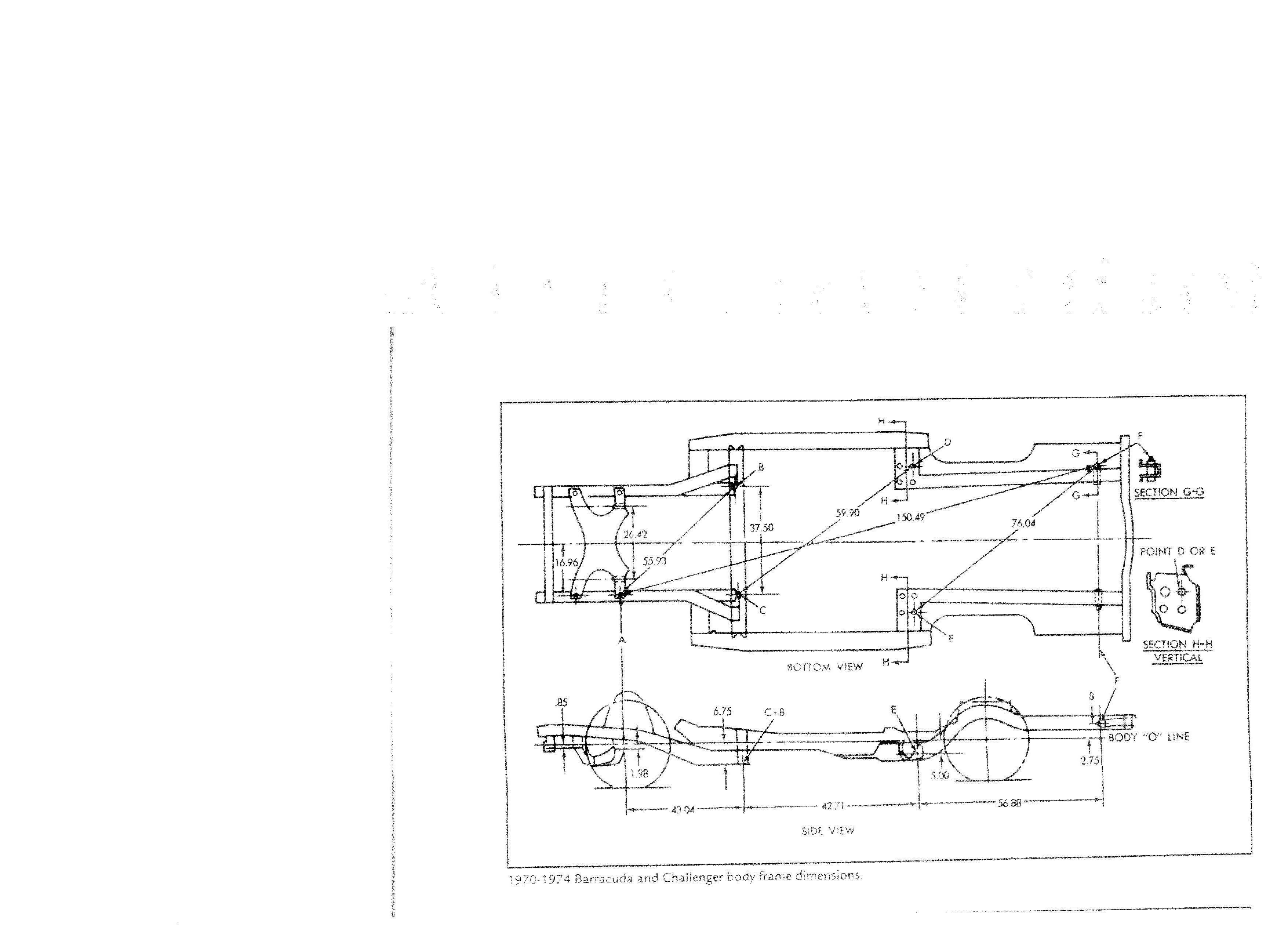

The front clip has to be under the car to be aligned with center section and the rear section.use the measurements to line up before you weld anything. there is enough movement in the inner fender and fender slots for movement. this is where you see the problem and where it can be corrected. get a string line front to back on center. This can be done with a jack stand or cinder block font and back. Measure off the inside rocker panel 27.5 to center. half of the 55" measurement. This has to be done. There are variations from car to car. You have to match the car how it was built.

Last edited:

Challenger RTA

Well-Known Member

I know what you are saying. An 1/16" on the back of the front clip can throw off the front.G is 34

The problem is that the radiator opening is 1/2 wider at the top than the bottom.

Last edited:

Challenger RTA

Well-Known Member

Cuda dimensions

Craig J

Well-Known Member

a little while later.

rklein71

Well-Known Member

My 71 driver during metal work, I didn't have to replace the inner fenders though.

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 1

- Views

- 280

- Replies

- 2

- Views

- 228

- Locked

- Replies

- 0

- Views

- 915