RedFoxesTco

Member

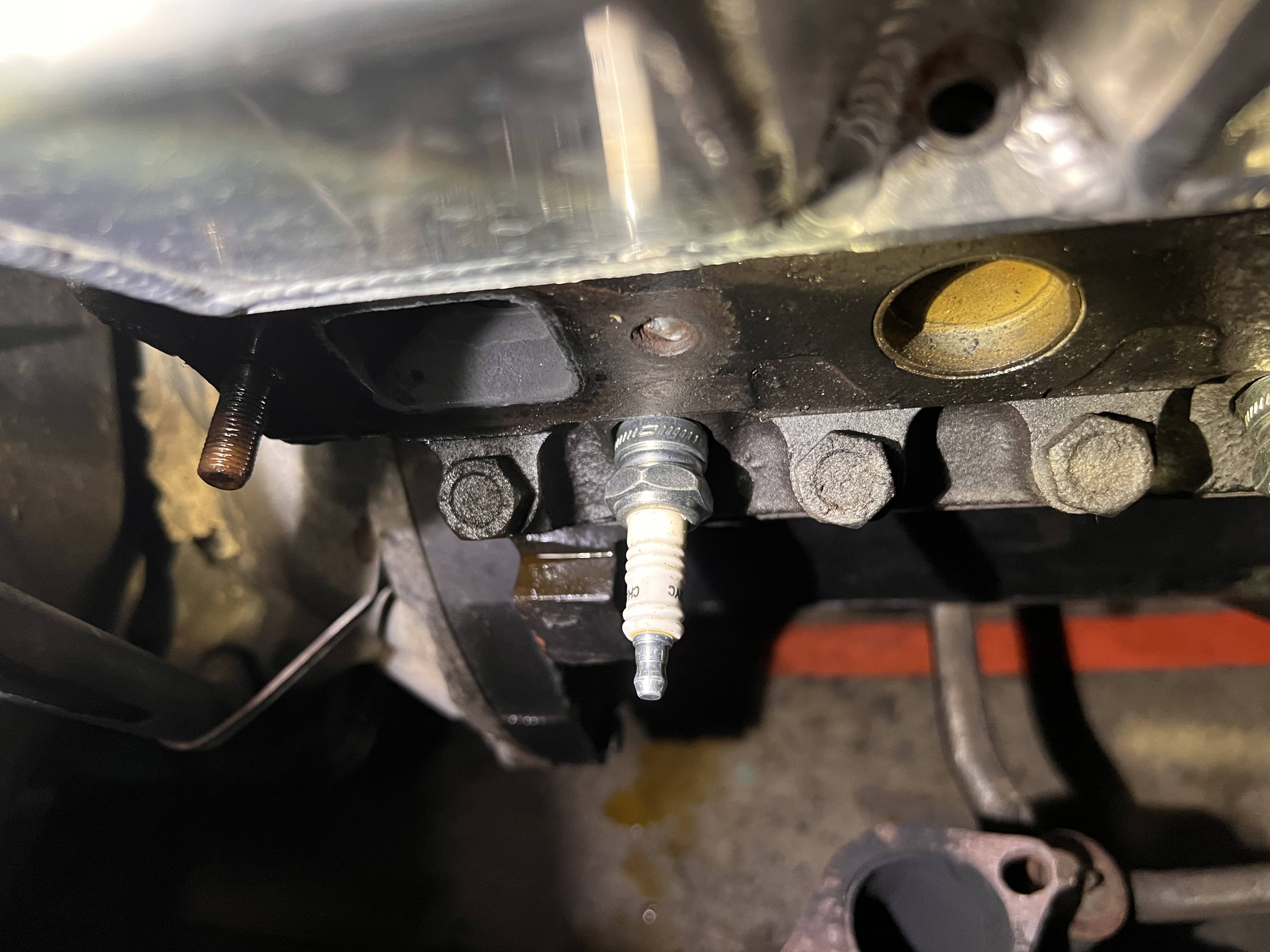

I broke off an exhaust stud while removing the old ones. 383 engine, still in car. It’s the second to last one on passenger side. Followed other users threads on drilling and extracting but no use.

- Is there any way for me to salvage this?

-Or will I have to remove the head and take to machine shop?

-Also, is it possible to remove without removing engine? Just installed new valley pan, manifold and carb. Am I going to have to get a new valley pan if so?

Thanks in advance for the help and advice. It’s was trying to replace manifold gaskets as I’ve had exhaust leaks

Oh! And is this a water port? Or can I leave it as is, deal with exhaust leak and sort out later?

- Is there any way for me to salvage this?

-Or will I have to remove the head and take to machine shop?

-Also, is it possible to remove without removing engine? Just installed new valley pan, manifold and carb. Am I going to have to get a new valley pan if so?

Thanks in advance for the help and advice. It’s was trying to replace manifold gaskets as I’ve had exhaust leaks

Oh! And is this a water port? Or can I leave it as is, deal with exhaust leak and sort out later?