ShadeTreeFixer

Member

Here’s the specs of my ride. What would be optimal initial, total timing?

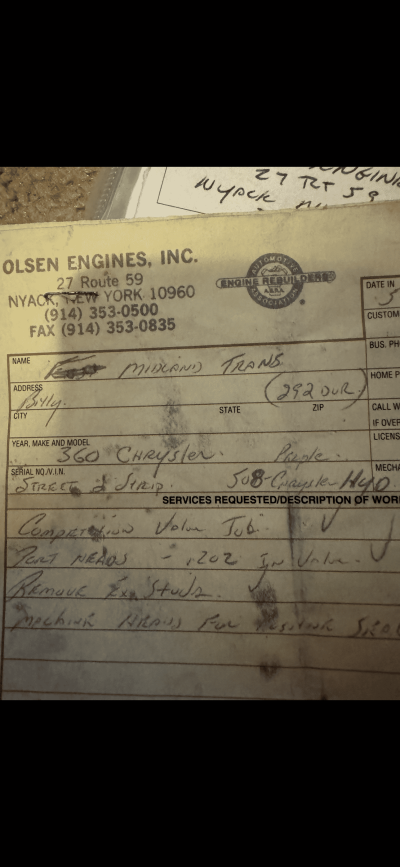

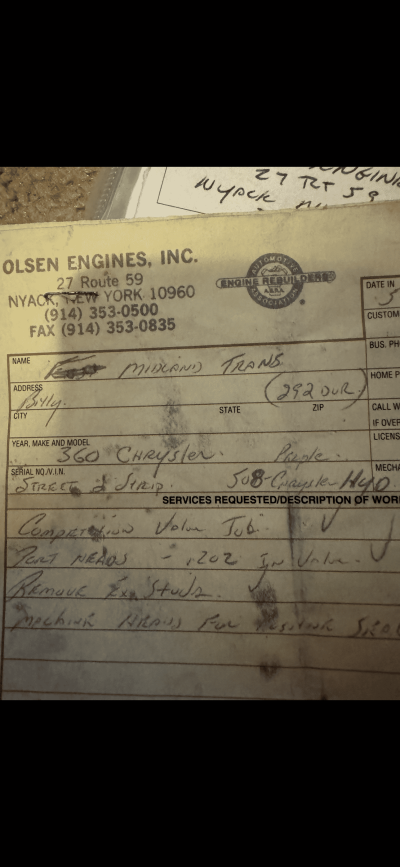

1972 Barracuda

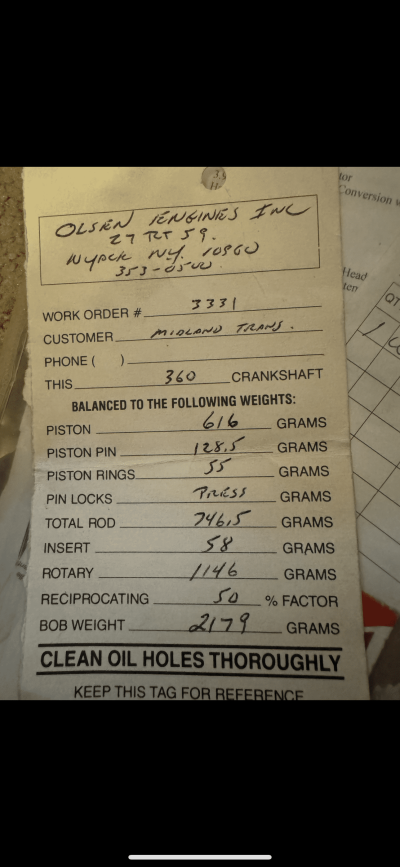

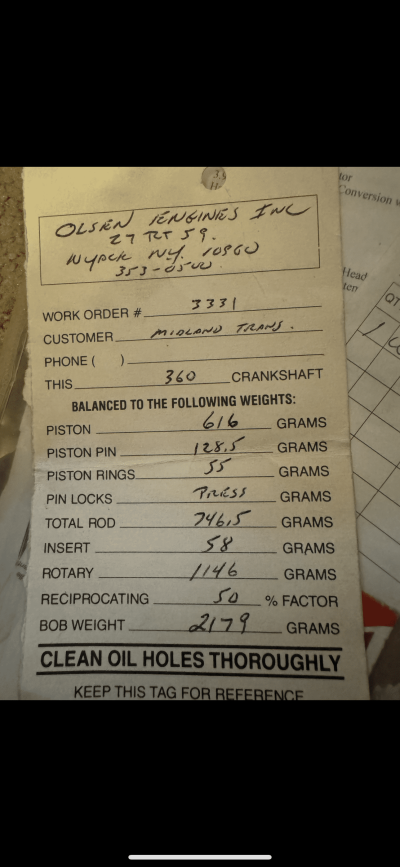

360 Chrysler

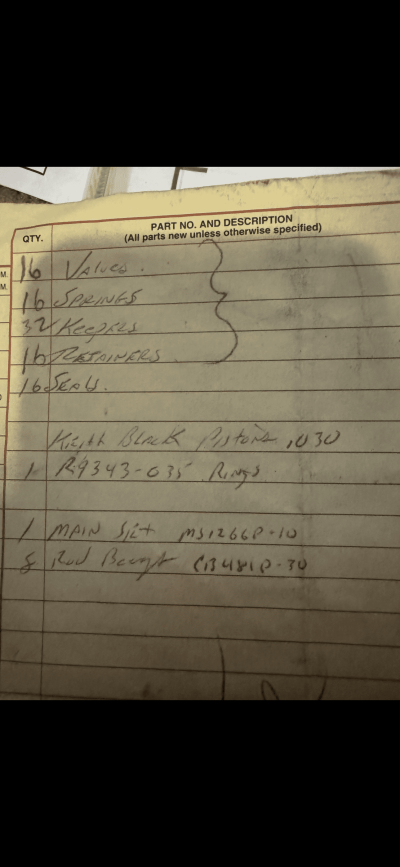

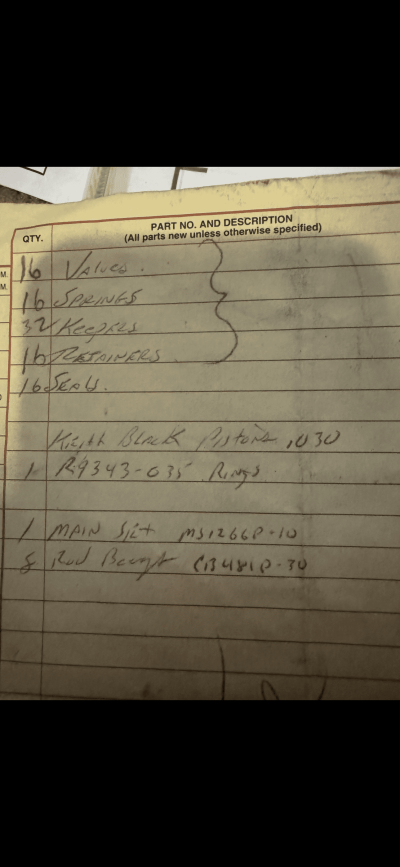

Over bored 0.03

Kieth Black Pistons

Mopar Purple Cam 509

MDS Distributor (light blue & light silver springs w/ purple bushing: estimated 19-20* of total advance)

Headman ceramic headers

Manual valve body tranny conversion 3600

My main question is how does the cam either affect timing or would need timing changes?

Also does the manual valve conversion require timing adjustments or is that not affected but requires timing to be precise?

This is a car that I purchased from a guy at a great price because it was making a grinding noise on the front passenger wheel. I though bearing so when I took it apart I found the new brake pad was installed backwards. And this was done at a shop!!!! Anyways I’m going through the entire car by principle.

Thanks in advance.

I set it to 16* initial and total was very close to 35*/38* total but the rpm’s would really bog at 900-1100. Almost had to get it to 12000 rpm at idle. That’s gotta be too much right. Maybe this is just a carb tuning thing or maybe my timing values aren’t correct for the installed pistons, cam, etc..

1972 Barracuda

360 Chrysler

Over bored 0.03

Kieth Black Pistons

Mopar Purple Cam 509

MDS Distributor (light blue & light silver springs w/ purple bushing: estimated 19-20* of total advance)

Headman ceramic headers

Manual valve body tranny conversion 3600

My main question is how does the cam either affect timing or would need timing changes?

Also does the manual valve conversion require timing adjustments or is that not affected but requires timing to be precise?

This is a car that I purchased from a guy at a great price because it was making a grinding noise on the front passenger wheel. I though bearing so when I took it apart I found the new brake pad was installed backwards. And this was done at a shop!!!! Anyways I’m going through the entire car by principle.

Thanks in advance.

I set it to 16* initial and total was very close to 35*/38* total but the rpm’s would really bog at 900-1100. Almost had to get it to 12000 rpm at idle. That’s gotta be too much right. Maybe this is just a carb tuning thing or maybe my timing values aren’t correct for the installed pistons, cam, etc..

Last edited: