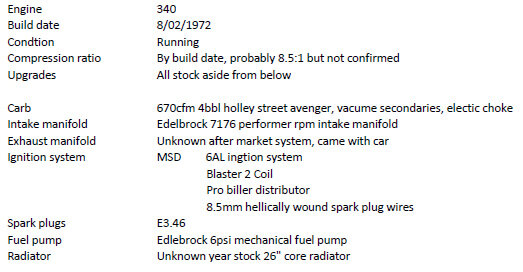

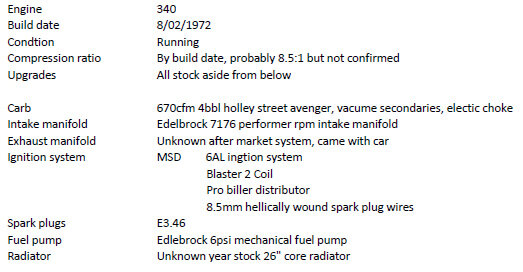

After reading around about the differences between the years the 340 block was produced and available performance upgrades, I'm now trying to work out a logical order to building a streetable but aggresive 340 (not in that order)! To also note, my older brother has a 67 Camaro with a 350 replacement engine, approx 340hp, 420 ft lbs of tq andits completely unexceptible for the Chev to be faster. Its also approx 100lbs lighter than my Chall due to factory options. So in the nature of Detroit, help me restore the natural order of the muscle car eara and put the Challenger back on top!

To note, I'd rather not go down the path of forced induction or strocking and boring. Prefering to keep the concept of the 340 and work the engine as far as possible to a streetable rocket that'll last. ie, not a maintance monster.

How probable is it for the block to be a time bomb due to warp or cracking?

Because in Australia a full block inspection is high enough in price that it warants the purchase of a replacement 340 or R3 for summit racing.

Phase 1: Maximise Air flow

Cam

Push rods

Rockers

Cylinder heads

Later on port everything which air flows through

Phase 2: Increase compression ratio

Bore engine 5 thousandeths over to clean it up a bit

Compression ratio was dropped in 1972 by changing piston wrist pin location - reverse this by changing pistons

Compression ratio should be back to 10.5 to one?

Phase 3:

Tune the system so it all functions harmonisouly

Does this sound logical interms of order and changes?

Are their higher priorities/recomendations?

How probable is it for the block to be a time bomb due to warp or cracking?

Compression ratio should be back to 10.5 to one with piston change?

Cheers.

To note, I'd rather not go down the path of forced induction or strocking and boring. Prefering to keep the concept of the 340 and work the engine as far as possible to a streetable rocket that'll last. ie, not a maintance monster.

How probable is it for the block to be a time bomb due to warp or cracking?

Because in Australia a full block inspection is high enough in price that it warants the purchase of a replacement 340 or R3 for summit racing.

Phase 1: Maximise Air flow

Cam

Push rods

Rockers

Cylinder heads

Later on port everything which air flows through

Phase 2: Increase compression ratio

Bore engine 5 thousandeths over to clean it up a bit

Compression ratio was dropped in 1972 by changing piston wrist pin location - reverse this by changing pistons

Compression ratio should be back to 10.5 to one?

Phase 3:

Tune the system so it all functions harmonisouly

Does this sound logical interms of order and changes?

Are their higher priorities/recomendations?

How probable is it for the block to be a time bomb due to warp or cracking?

Compression ratio should be back to 10.5 to one with piston change?

Cheers.