I wanted to cover specific data regarding "Survivor" versus a "Ground Up" Restorations. This information originated in another Forum but I wanted to convey the steps & processes here. I'll ramp things up quickly by posting the pictures here on a daily basis. Let me start by saying that the two areas are completely different than one would imagine. With a survivor, many assume that it should be much easier of a project than starting with a worn out, extensively used vehicle. This could not be farther from the truth!!! It wasn't until restoring the Valiant that our team understood the true meaning of the word RESTORE! As this thread progresses, I will post the procedural variations that contrast the two processes.

Most Basket Case or Ground Up projects can be compared to a General Contractor in the Construction Industry. You out source many components, let the Specialists work their magic and re-assemble the parts when they are returned. For example, enthusiasts can rely on Companies such as Lengendary Interiors to locate NOS materials, stitch together the correct patterns and presto......you have a "new Factory" interior! With relatively minimal involvement you are ready to bolt in a major part of the project! With a "Survivor" the original interior exhibits 40+ years of wear, tear and dirt. No longer does one have the leisure of subcontracting the work to make things look new again. You literally have to restore every component that originally came on the vehicle from the Factory.

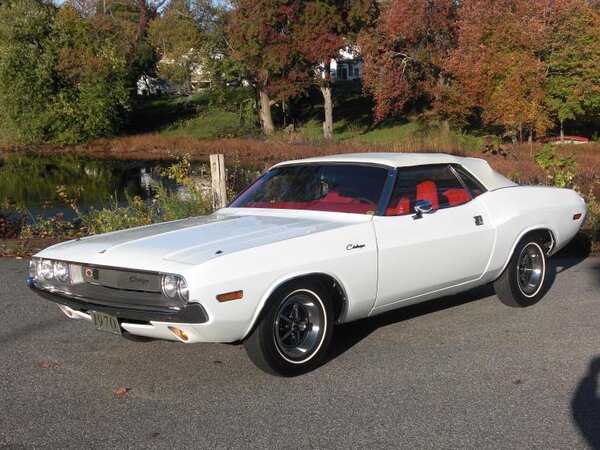

How many restorers have attempted to make 40+ year old rust stained carpet look and smell new again? What about removing 40 years of grime and dirt from the mesh material of seat inserts? Or replicating every detail from an old weathered K Frame assembly? (See Pic Below) Keep in mind that there can be no evidence of tampering with these original materials or parts when completed! The "Ground Up" Restoration for the Cuda and Challenger was a necessary preparation towards the extreme difficulties that faced us during the Valiant Project. Having been involved with both types of restorations, we will share our experiences from each vantage point. Please feel free to post your own restoration stories, questions or observations. Let's get started!

Before

After

Most Basket Case or Ground Up projects can be compared to a General Contractor in the Construction Industry. You out source many components, let the Specialists work their magic and re-assemble the parts when they are returned. For example, enthusiasts can rely on Companies such as Lengendary Interiors to locate NOS materials, stitch together the correct patterns and presto......you have a "new Factory" interior! With relatively minimal involvement you are ready to bolt in a major part of the project! With a "Survivor" the original interior exhibits 40+ years of wear, tear and dirt. No longer does one have the leisure of subcontracting the work to make things look new again. You literally have to restore every component that originally came on the vehicle from the Factory.

How many restorers have attempted to make 40+ year old rust stained carpet look and smell new again? What about removing 40 years of grime and dirt from the mesh material of seat inserts? Or replicating every detail from an old weathered K Frame assembly? (See Pic Below) Keep in mind that there can be no evidence of tampering with these original materials or parts when completed! The "Ground Up" Restoration for the Cuda and Challenger was a necessary preparation towards the extreme difficulties that faced us during the Valiant Project. Having been involved with both types of restorations, we will share our experiences from each vantage point. Please feel free to post your own restoration stories, questions or observations. Let's get started!

Before

After

Last edited: