340challconvert

Well-Known Member

Some information on the Federal Pumps regarding spring pressures;

1969 and up Federal 1.06 pump, there were 3 variations of the pump, all with different part numbers. The pumping mechanism and repairs kits where the same, because the internals were all the same except one component. The one component not serviced individually on federal pump was the flow control valve. It was a custom fit to the housing and if needing replacement, you had to by a new pump assembly. Not the reservoir, just pump. The flow control valve was also the relief valve.

So what was the difference? Operating pressure. The A bodies were 750 to 850 psi, B bodies and hemi 950 to 1050psi. Also shared with the big block A bodies in 69 and the AAR/TA in 70. The C bodies except 318 1100-1300psi.

The parts manual calls out the 3 different part numbers for pumps, 289131, 130, 129 respectively. The Service manual describes the pressure differences, and the Chrysler training video clearly spells out these difference and states that Flow control valves cannot be swapped between pumps, nor can pumps be exchanged between body styles. “Get the correct pump part number for the car and install it”.

They also are very clear in stating the pump hose also plays an important role in operation and quietness of the pump. The tube bends and such probably provide the back press necessary along with the pulley/motor combination that made the flow control valve operate correctly for the car model. There also where difference in steering gear pump part numbers. So it was a system set up. Motor, pulley/hose, steering gear, and pump.

Current parts stores do not make a distinction. You either get a Federal pump or the Saginaw. Go to the rebuilder sites and it is the same. They just send you a federal pump, no distinction of the different operating pressures. How could you let 3 variations of a pump with different operating pressures go unmarked without a specific identification?

When questioning some rebuilders, they did not have an answer and stated the system would still be ok and regulate itself. Again they do not make a distinction. They just rebuild the pump. An easy task by the way for a federal pump. Since the flow valve is simple and stays with the housing, as long as they are not mixing and matching on the repair line you may be ok if you sent your original in for a rebuild.

But if you buy at the local parts store a remanufactured federal pump, you do not know which of the 3 variations you are getting. Again, maybe this does not matter, but maybe you have had some pumps that did not feel right on your car.

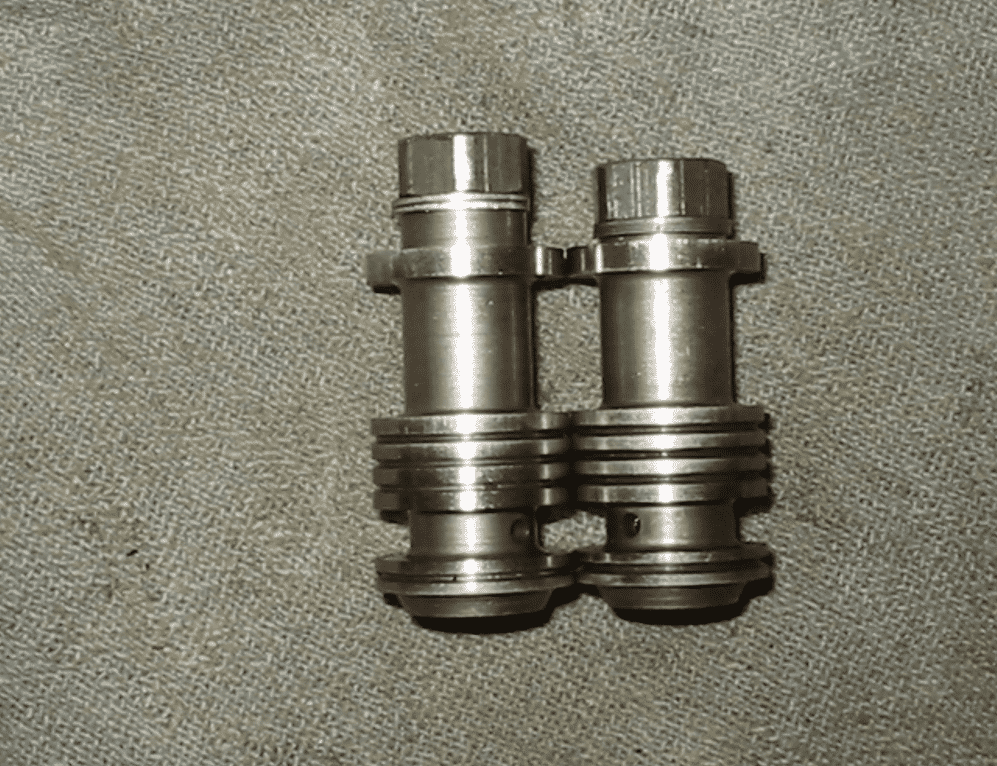

Attached are 2 different federal pumps with different stamp markings, and you can see the difference in the flow control valves. The flow section is the same, but the pressure relief is controlled by spring and shims. Thank you to the original author of this article (not me) Enjoy

1969 and up Federal 1.06 pump, there were 3 variations of the pump, all with different part numbers. The pumping mechanism and repairs kits where the same, because the internals were all the same except one component. The one component not serviced individually on federal pump was the flow control valve. It was a custom fit to the housing and if needing replacement, you had to by a new pump assembly. Not the reservoir, just pump. The flow control valve was also the relief valve.

So what was the difference? Operating pressure. The A bodies were 750 to 850 psi, B bodies and hemi 950 to 1050psi. Also shared with the big block A bodies in 69 and the AAR/TA in 70. The C bodies except 318 1100-1300psi.

The parts manual calls out the 3 different part numbers for pumps, 289131, 130, 129 respectively. The Service manual describes the pressure differences, and the Chrysler training video clearly spells out these difference and states that Flow control valves cannot be swapped between pumps, nor can pumps be exchanged between body styles. “Get the correct pump part number for the car and install it”.

They also are very clear in stating the pump hose also plays an important role in operation and quietness of the pump. The tube bends and such probably provide the back press necessary along with the pulley/motor combination that made the flow control valve operate correctly for the car model. There also where difference in steering gear pump part numbers. So it was a system set up. Motor, pulley/hose, steering gear, and pump.

Current parts stores do not make a distinction. You either get a Federal pump or the Saginaw. Go to the rebuilder sites and it is the same. They just send you a federal pump, no distinction of the different operating pressures. How could you let 3 variations of a pump with different operating pressures go unmarked without a specific identification?

When questioning some rebuilders, they did not have an answer and stated the system would still be ok and regulate itself. Again they do not make a distinction. They just rebuild the pump. An easy task by the way for a federal pump. Since the flow valve is simple and stays with the housing, as long as they are not mixing and matching on the repair line you may be ok if you sent your original in for a rebuild.

But if you buy at the local parts store a remanufactured federal pump, you do not know which of the 3 variations you are getting. Again, maybe this does not matter, but maybe you have had some pumps that did not feel right on your car.

Attached are 2 different federal pumps with different stamp markings, and you can see the difference in the flow control valves. The flow section is the same, but the pressure relief is controlled by spring and shims. Thank you to the original author of this article (not me) Enjoy