JKCuda

Well-Known Member

So, my project is continuing to grow by the minute it seems.

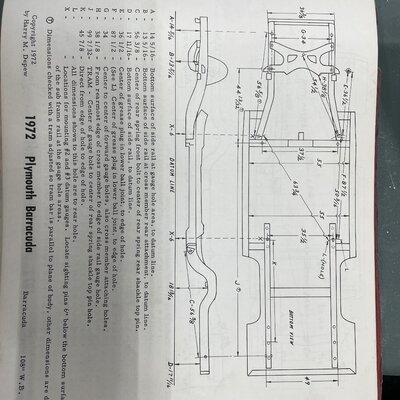

While my powerplant is out I'm considering replacing the rad support as well as the inner fenders and possibly the firewall on my 72 Cuda. The rad support and the driver side inner fender definitely needs replaced, the other inner fender and the firewall I'm not 100% sure yet as I'm in the process of stripping the paint/coating the previous owner laid over top to see what I'm working with.

I've never welded or done any type of metal work, and any type of body work I've done has been limited to bondo patches and some basic fiberglass. Are there any good resources out there for E bodies where I could read up on some info or even some guides to show me what all this process entails? I have a friend who can weld and offered to help, so I have that, but I'm a hands on type guy and would really like to learn and at least do some of the work. This car is a resto-mod so I'm not worried about factory specific yada yada yada, just want a solid shell.

Any tips or links would be much appreciated! I've struggled to find much information other than pictures of others projects.

While my powerplant is out I'm considering replacing the rad support as well as the inner fenders and possibly the firewall on my 72 Cuda. The rad support and the driver side inner fender definitely needs replaced, the other inner fender and the firewall I'm not 100% sure yet as I'm in the process of stripping the paint/coating the previous owner laid over top to see what I'm working with.

I've never welded or done any type of metal work, and any type of body work I've done has been limited to bondo patches and some basic fiberglass. Are there any good resources out there for E bodies where I could read up on some info or even some guides to show me what all this process entails? I have a friend who can weld and offered to help, so I have that, but I'm a hands on type guy and would really like to learn and at least do some of the work. This car is a resto-mod so I'm not worried about factory specific yada yada yada, just want a solid shell.

Any tips or links would be much appreciated! I've struggled to find much information other than pictures of others projects.

Last edited: