74stroker

Well-Known Member

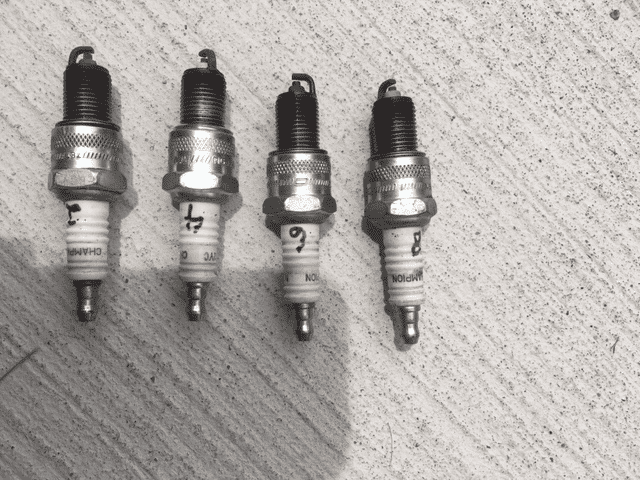

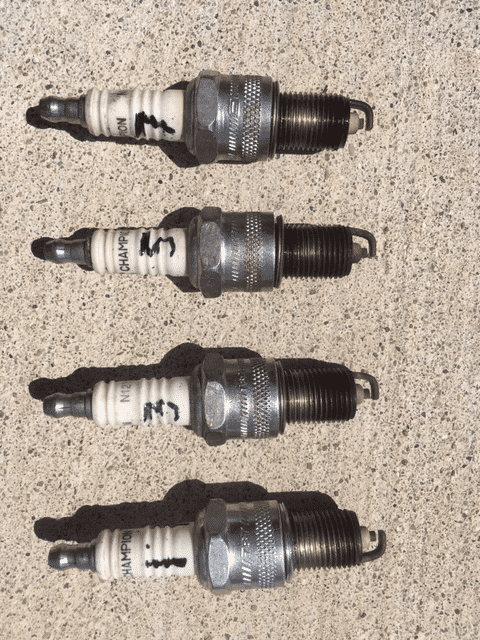

Photos to go with previous post: plugs pulled on June 1: #4 had lower compression and oil on threads and electrode

Horoscope? I never put any stock in those things!I have photos of cylinders 2,4,6, and 8 using horoscope.

I don’t know. If needed I would expect the builder to have them...Are there studs for the main caps?

Thanks heminut. I would run this test, but worry I might do more damage to engine. Pretty sure the pistons got too hot because either plugs were too hot N12Y—-should have used N9Y, and fuel cap I had was non-venting, creating vacuum in tank that held fuel back.Old time mechanics always said that if it smokes when you're accelerating it's oil getting by the rings, and if it smokes when decelerating is oil getting through the valve guides.

Mystery solved (I hope). Builder pulled head and found head gasket was blown on No 6 cylinder. motor pulled oil from galley into cylinder through pcv valve.

Thanks pschosser. I was relieved it was not burned pistons again, though I couldn't see how this would have occurred with such limited and easy driving. The builder and I will be having a talk this week before completing the repairs. I will be sure this is part of the discussion. None of your causes for blown h. gaskets seem to apply here, as the car was not driven hard. Builder suggested it might have misfired (I never heard it knock and ran on premium gas) or that the bolt pattern on the head was wide where the failure occurred.That's good news, indeed. This is an easy fix. It's possible there was a defect in the gasket, or some speck of dirt was in the wrong place when installed prior. I presume the "builder" will confirm the block deck and head are true and flat prior to reassembly. I recommend you ask them to make sure they at least say it was checked.

I've blown a few head gaskets in my driving past. The bulk of them were from poor cooling or over heating. And, of course, hard driving.

Builder suggested it might have misfired (I never heard it knock and ran on premium gas) or that the bolt pattern on the head was wide where the failure occurred.