You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Run on

- Thread starter oneof52

- Start date

Challenger RTA

Well-Known Member

I shave everyday.

mrmopar340

Well-Known Member

I do some days...I shave everyday.

72RoadRunnerGTX

Well-Known Member

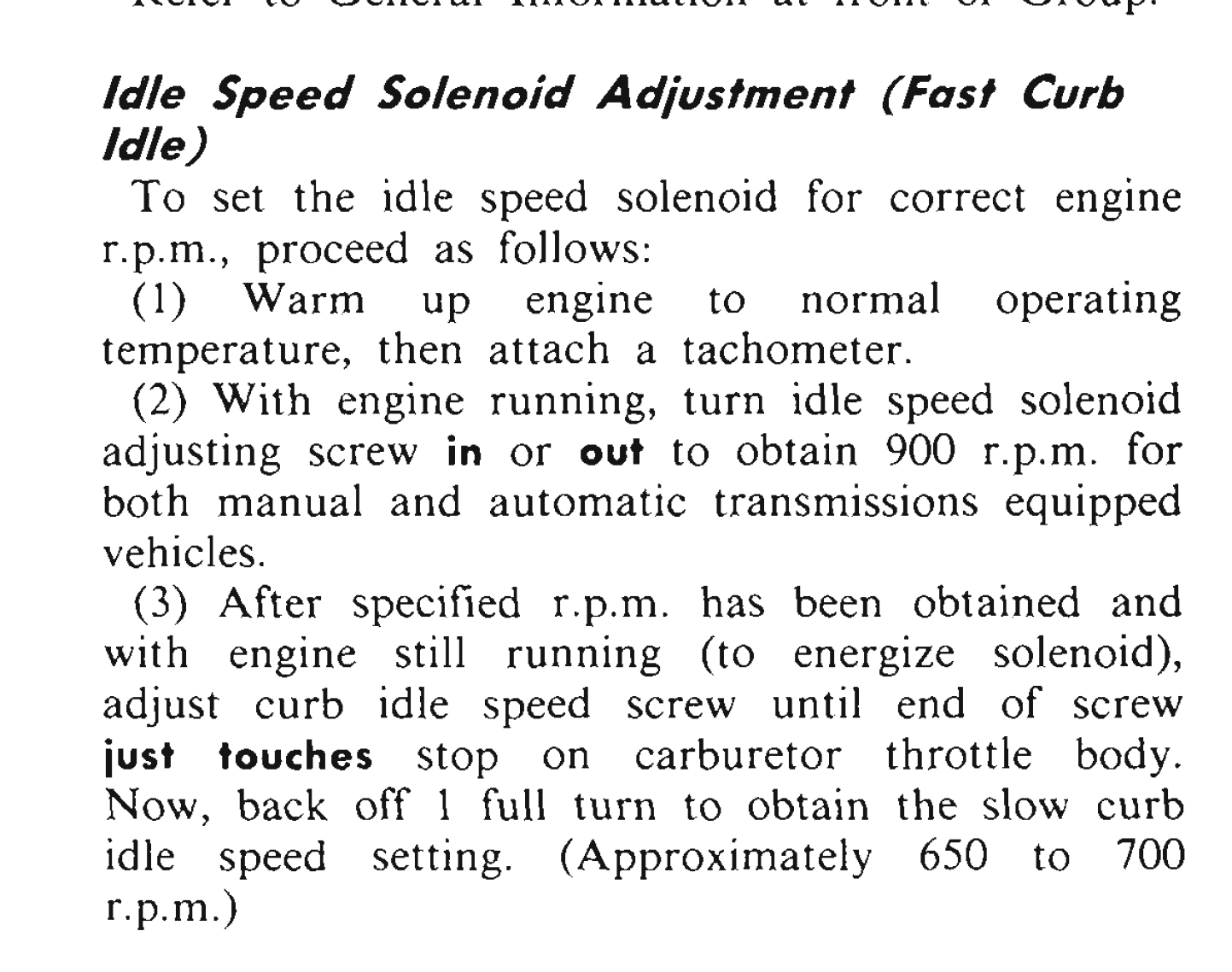

All OE six-packs came with idle solenoids as a stock correctly tuned (as factory spec’d) six-pack tended to diesel without one no matter what optional equipment or anything related to emissions control. Be sure the solenoid still functions and set as described in the FSM.

Original replacements are rare and expensive, repos are junk. If exact original appearance is not too concerning there are functional quality alternatives.

Original replacements are rare and expensive, repos are junk. If exact original appearance is not too concerning there are functional quality alternatives.

6PKRTSE

Well-Known Member

- Joined

- Feb 3, 2010

- Messages

- 957

- Reaction score

- 546

I don't have an idle solenoid on my sixpack and there hasn't been one on there in over 34 years and never once has it dieseled or run onAll OE six-packs came with idle solenoids as a stock correctly tuned (as factory spec’d) six-pack tended to diesel without one no matter what optional equipment or anything related to emissions control. Be sure the solenoid still functions and set as described in the FSM.

View attachment 118860

Original replacements are rare and expensive, repos are junk. If exact original appearance is not too concerning there are functional quality alternatives.

View attachment 118862

72RoadRunnerGTX

Well-Known Member

Doesn’t sound like a very stock motor or tune. Every stock six-pack I’ve owned or tuned in the last 50 years would tend to diesel without a functional correctly adjusted idle solenoid. As a matter of fact, anything requiring anything close to 900 rpm for a curb idle speed would diesel without a solenoid to close off the throttle. Wonder why the factory decided to put solenoids on the set-up if it wasn’t needed.Then I tell them that I have a .815 lift in my street car and it does not diesel when I shut mine off???

Last edited:

There should be no need to use the solenoid to prevent run-on or dieseling.

A six pak properly set up does not require this at all.

E3 plugs are not needed.

900 rpm is too high for most engines

there are many "details" that are being missed here, it costs money to get that level of work.

A six pak properly set up does not require this at all.

E3 plugs are not needed.

900 rpm is too high for most engines

there are many "details" that are being missed here, it costs money to get that level of work.

Last edited:

72RoadRunnerGTX

Well-Known Member

The facts remain, for this discussion, the original factory specifications call for a 900-rpm curb idle speed and every six-pack left the factory with a functional idle solenoid to prevent run-on/dieseling. If your custom tune does not run-on, good for you. If your tune, be it close to original or something custom, does run-on, a functional and correctly adjusted idle solenoid will stop it as it was originally designed to do.There should be no need to use the solenoid to prevent run-on or dieseling.

A six pak properly set up does not require this at all.

E3 plugs are not needed.

900 rpm is too high for most engines

there are many "details" that are being missed here, it costs money to get that level of work.

Thank you everyone, extremely helpful. Just a question, where is the solenoid wire connected to at the other side, and should it drop down once in drive.

Adjustments will be done today or tomorrow and will report with details

Adjustments will be done today or tomorrow and will report with details

72RoadRunnerGTX

Well-Known Member

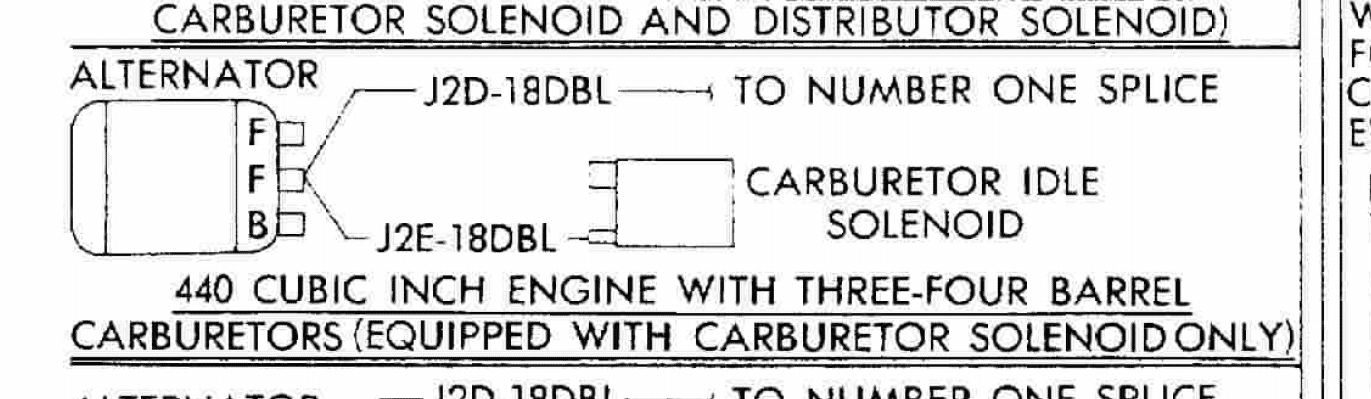

The power for the solenoid is sourced from the Ignition 1 circuit in the engine harness, Ignition run position of the ignition switch. Should only “drop-down” or de-energize when the key is switched off.

Vinny

Active Member

If you go back to my engine bay picture, post #17, you can see that it connects to one side on the ballast resistor, to the special connector, which supplies power as soon as the ignition is turned on. And yes, it is always energized, until you turn off the key.Thank you everyone, extremely helpful. Just a question, where is the solenoid wire connected to at the other side, and should it drop down once in drive.

Adjustments will be done today or tomorrow and will report with details

Vinny

Active Member

Exactly.The power for the solenoid is sourced from the Ignition 1 circuit in the engine harness, Ignition run position of the ignition switch. Should only “drop-down” or de-energize when the key is switched off.

72RoadRunnerGTX

Well-Known Member

Specifically for a ’70, the solenoid power is doubled up at the ign1 terminal at one of the field connectors at the alternator, same circuit at the ballast resistor shown on the ’69 picture above.

Interesting type-O, “Three-four barrel carburetors”?

Interesting type-O, “Three-four barrel carburetors”?

Thank you very much now I have more information and can trace. Awesome group, happy I joined this forum.Specifically for a ’70, the solenoid power is doubled up at the ign1 terminal at one of the field connectors at the alternator, same circuit at the ballast resistor shown on the ’69 picture above.

Interesting type-O, “Three-four barrel carburetors”?

View attachment 118866

Specifically for a ’70, the solenoid power is doubled up at the ign1 terminal at one of the field connectors at the alternator, same circuit at the ballast resistor shown on the ’69 picture above.

Interesting type-O, “Three-four barrel carburetors”?

View attachment 118866

Well, did not take long , removed vacuum advance from the distributor, warmed up engine, retard the timing to 12 degrees BTC , turn back the curb idle solenoid screw to 925, unplug solenoid, adjusted rpm to 675 , adjusted fuel air mixture . Plugged back the solenoid, put back vacuum on distributor blocked everything up.

Success - engine is calmer, no more choppy and no more dieseling.

Thank you everyone for all your help

Success - engine is calmer, no more choppy and no more dieseling.

Thank you everyone for all your help

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 6

- Views

- 427