Orange Man

Member

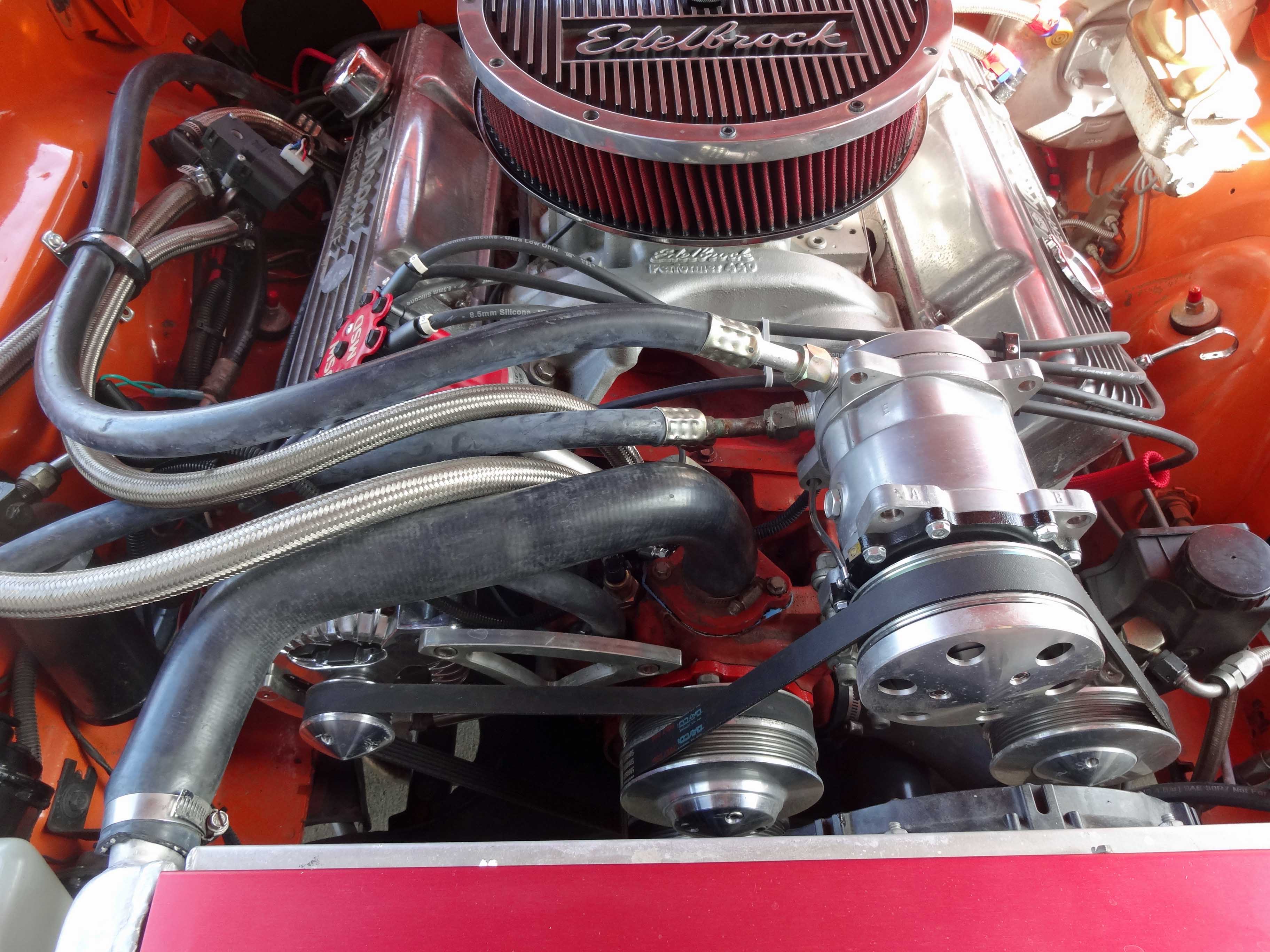

I have gone through a lot of the posts on this site concerning heating issues with the 440 Magnum. Not many fit my situation. First of all, I bought this car from my friends widow. He bought it off of Ebay from the guy that restored it in Florida and had it shipped to Texas. I did not know my friend long before he pasted suddenly and he never mentioned overheating problems but then again he did not have it long and did not get to drive it much. I do not know if it was having heating problems then. The only thing he changed on the car was to put a Holley Sniper EFI. He had a lot of problems with it which some were caused by the installers.

Here is what I have done to it to try and fix the problem. I replaced the 13# radiator cap with a 16#. Ran the car and it heated up like before. I replaced the 160* thermostat with a 180* thermostat. It helped some but not much. I replaced all the plug wires because 5 out of 8 were burned through. They are too close to the headers but there is not much I can do except use plug wire looms and retainers. Runs better now.

Here is what is going on when it starts to heat up. Both electric fans are pullers. The bottom fan comes on at about 160*. It takes it several minutes before it gets to 180* The thermostat opens like it should, then the upper fan comes on when the temp gets to 180* but then the lower fan shuts off and will not come back on when the engine starts to heat up. The temp stays at about 195 for a while then goes to 210* and stays there for about 5 minutes then will steadly climb to 250* by then I will have shut it off. It takes driving about 20 minutes for all this to happen. I can hear the water gurguling in the radiator when it hits 235*. This is all on an 80 to 90 degree day. I use an infrared thermometer to check the temps. The temps at the thermostat housing are very close to the gauge.

Here are my thoughts. I think the EFI programing is screwed up and should allow both fans to run at the same time not just one. I think this because of all the clutter in front of the radiator and not enough grille to let a lot of air through to begin with. The radiator is a 2 row 26" radiator. The number of rows may be not enough for this setup. Also, there is a puller fan that pulls air away from the condenser towards the grille. It is actuated by the A/C switch on the dash. It does not run unless the AC is turned on. Should the fan in front of the AC condenser be a pusher which would push air towards the radiator instead of pulling air through the condenser towards the grille?

From friends of mine that got to know my friend "Will" before I met him, they said the car ran fine with no heating problems before Will had the Sniper put it. I am thinking that the programing got messed up and will not allow the bottom fan to come on. It gets awful hot in that engine compartment in 90+* Texas weather.

I think there is a combination of things going on that all contribute to the heating problem.

I was always a SBC guy and have been thrown into the Mopar crowd by purchasing this car. I like a challenge but this is begining to work on me because of the electronics stuff.

Please be gentle.

Here is what I have done to it to try and fix the problem. I replaced the 13# radiator cap with a 16#. Ran the car and it heated up like before. I replaced the 160* thermostat with a 180* thermostat. It helped some but not much. I replaced all the plug wires because 5 out of 8 were burned through. They are too close to the headers but there is not much I can do except use plug wire looms and retainers. Runs better now.

Here is what is going on when it starts to heat up. Both electric fans are pullers. The bottom fan comes on at about 160*. It takes it several minutes before it gets to 180* The thermostat opens like it should, then the upper fan comes on when the temp gets to 180* but then the lower fan shuts off and will not come back on when the engine starts to heat up. The temp stays at about 195 for a while then goes to 210* and stays there for about 5 minutes then will steadly climb to 250* by then I will have shut it off. It takes driving about 20 minutes for all this to happen. I can hear the water gurguling in the radiator when it hits 235*. This is all on an 80 to 90 degree day. I use an infrared thermometer to check the temps. The temps at the thermostat housing are very close to the gauge.

Here are my thoughts. I think the EFI programing is screwed up and should allow both fans to run at the same time not just one. I think this because of all the clutter in front of the radiator and not enough grille to let a lot of air through to begin with. The radiator is a 2 row 26" radiator. The number of rows may be not enough for this setup. Also, there is a puller fan that pulls air away from the condenser towards the grille. It is actuated by the A/C switch on the dash. It does not run unless the AC is turned on. Should the fan in front of the AC condenser be a pusher which would push air towards the radiator instead of pulling air through the condenser towards the grille?

From friends of mine that got to know my friend "Will" before I met him, they said the car ran fine with no heating problems before Will had the Sniper put it. I am thinking that the programing got messed up and will not allow the bottom fan to come on. It gets awful hot in that engine compartment in 90+* Texas weather.

I think there is a combination of things going on that all contribute to the heating problem.

I was always a SBC guy and have been thrown into the Mopar crowd by purchasing this car. I like a challenge but this is begining to work on me because of the electronics stuff.

Please be gentle.