Hey all, I need to replace the trunk pan and part of the extensions. The car came with a two piece pan and I'm Not sure the best way to install. I've never done a pan so trying to gather as much info as possible. Do you overlap the panels and spot weld or butt them up? I've read different ways to do this. Should I put the pans together out of the car with clecos or spot welds and install as one piece or separate? I want to make sure I get all the lines even as possible. I think I want to cut them in just below the shock tower humps at the base of the pan as they are perfectly fine and want to keep as much factory metal as possible. The majority of the rust is in the tray area. Any tips are appreciated, thanks in advance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trunk Pan Replacement Help Needed

- Thread starter 1moretoy

- Start date

Katfish

Well-Known Member

I thought the whole point of offering 2 piece is that it's not possible to install a 1 piece without the whole backend apart?

larry4406

Well-Known Member

Not my pictures. Saved from the net years ago. Thanks to the OP whoever you are.

Shows a one piece pan being slid in.

Shows a one piece pan being slid in.

Adam

Well-Known Member

I haven’t seen your original trunk pan, so assuming it is as you describe, this is what I would recommend .

Before you do anything take pics and measurements of the gas tank supports on the bottom of the trunk pan. Even if you have/need new supports you need to know exactly where they go so the straps line up with the gas tank grooves.

Save that rubber grommet that has the wire going thru it. Pics of the jack and spare tire brackets.

If your tail panel is in good shape, leave it alone.

Do not lap weld any part of the trunk pan, it will be a source of embarrassment.

If you want to save as much original metal as you can, cut out the rotten areas of the trunk pan and drill out the spot welds for the gas tank supports with a spot weld cutter. NOT a regular drill bit.

Draw a line & cut the old trunk floor pieces out cleanly with a jig saw, thin 4 in cut off wheel, or body saw and you can use the pieces as a template to cut the new pieces slightly bigger (1/4 or less). Also mark where the tank support spot welds were drilled out. Mock them into place and scribe a line exactly where to trim the excess off the patches until you have a great fit.

Inspect the upper shock mounts for cracks, now is the time to fix them if they need it.

Use the new pieces as patches and butt weld them in from the BOTTOM wherever possible, this will reduce the amount of grinding you have to do in the trunk. Plug weld the new holes in the pan to the gas tank supports.

Same for the extensions, drill the spot welds and cut out the rot. Use the old piece as a template, etc.

Before you do anything take pics and measurements of the gas tank supports on the bottom of the trunk pan. Even if you have/need new supports you need to know exactly where they go so the straps line up with the gas tank grooves.

Save that rubber grommet that has the wire going thru it. Pics of the jack and spare tire brackets.

If your tail panel is in good shape, leave it alone.

Do not lap weld any part of the trunk pan, it will be a source of embarrassment.

If you want to save as much original metal as you can, cut out the rotten areas of the trunk pan and drill out the spot welds for the gas tank supports with a spot weld cutter. NOT a regular drill bit.

Draw a line & cut the old trunk floor pieces out cleanly with a jig saw, thin 4 in cut off wheel, or body saw and you can use the pieces as a template to cut the new pieces slightly bigger (1/4 or less). Also mark where the tank support spot welds were drilled out. Mock them into place and scribe a line exactly where to trim the excess off the patches until you have a great fit.

Inspect the upper shock mounts for cracks, now is the time to fix them if they need it.

Use the new pieces as patches and butt weld them in from the BOTTOM wherever possible, this will reduce the amount of grinding you have to do in the trunk. Plug weld the new holes in the pan to the gas tank supports.

Same for the extensions, drill the spot welds and cut out the rot. Use the old piece as a template, etc.

Last edited:

Adam

Well-Known Member

Ok; I was referring to your original trunk pan; I can not see what can be saved and what needs to be cut out. My post is general for others that will read this and not meant to be insulting. I have done many, many patch panels on a variety of cars. Usually I use the same technique.

Here is a link to my old photo album: Challenger

My trunk pics are generally #50-90, and 205, 206

Here is a link to my old photo album: Challenger

My trunk pics are generally #50-90, and 205, 206

there are holes that need to be made in the new pan like shock access holes maybe more .also put in the whole trunk extensions it will be a cleaner job check the frame rails underneath they might need replacing .also if you are going to weld them together out of the car put them in the car first get them fitted then make marks where you need to cut and weld might be a good idea to tack weld them together in the car then remove for final welding . they sell weld through primer use that on places where you can;t get to after it's all welded in best of luck keep us posted

340challconvert

Well-Known Member

Adam, really great electronic, detailed record of your restoration. Nice reference material

Phil

Phil

Ok; I was referring to your original trunk pan; I can not see what can be saved and what needs to be cut out. My post is general for others that will read this and not meant to be insulting. I have done many, many patch panels on a variety of cars. Usually I use the same technique.

Here is a link to my old photo album: Challenger

My trunk pics are generally #50-90, and 205, 206

340challconvert

Well-Known Member

I welded and installed the two piece center seamed AMD panels. I liked AMD because of the pre-drilled holes in the panels.

moparleo

Well-Known Member

- Joined

- Oct 17, 2011

- Messages

- 7,117

- Reaction score

- 1,917

Now mini-tubs are in the mix. You need a complete game plan before you cut or weld anything.

If you don't have on hand help from someone who has done this before, You will need to do a lot of reseach online, in books etc...

A Mopar body shop is your best reference . Here is a guy I know up in Canada who does excellent Restoration work and can help you.

You should also join this site. An excellent source for E-body owners.

E-Bodies

ALAN GALLANT AUTOMOTIVE RESTORATION

If you don't have on hand help from someone who has done this before, You will need to do a lot of reseach online, in books etc...

A Mopar body shop is your best reference . Here is a guy I know up in Canada who does excellent Restoration work and can help you.

You should also join this site. An excellent source for E-body owners.

E-Bodies

ALAN GALLANT AUTOMOTIVE RESTORATION

From speaking with people it doesn't sound that difficult to minitub. I'll probably start this weekend hopefully.Now mini-tubs are in the mix. You need a complete game plan before you cut or weld anything.

If you don't have on hand help from someone who has done this before, You will need to do a lot of reseach online, in books etc...

A Mopar body shop is your best reference . Here is a guy I know up in Canada who does excellent Restoration work and can help you.

You should also join this site. An excellent source for E-body owners.

E-Bodies

ALAN GALLANT AUTOMOTIVE RESTORATION

6PKRTSE

Well-Known Member

- Joined

- Feb 3, 2010

- Messages

- 873

- Reaction score

- 466

Not bad to do the pan and mini-tub. I did mine. Also moved the springs 3" inboard. I can fit a 315/60/15 drag radial or also use a 29.5x10.5W slick on 12" wide wheels.

Take many photos and measurements for reference, then take more photos, maybe even a video.

I use a spot weld cutter to remove factory welds, remove old panels, and straighten out the flanges where the spot welds were for a nice fit up when the new panel goes in.

Agree with @Adam, DO NOT overlap panels where factory did not overlap panels. Make the nicest butt weld you can and grind top bottom of seam. Most other people don’t like it and it will always look like a repair job vs a restoration, but a butt seam is much more work overall and requires more skill to accomplish nicely.

With the 2 piece pan I would tackle one side first, check reference points, then tack in place. Fit second side, check reference points, then tack in place. Re-check reference points and start welding up seams.

I find 2 piece pans are easier to install and adjust if needed (some do need it), than the one piece due to the size and the repro stamping does not always fit as is. If the tail pan needed replacement and was removed I would consider a 1 piece install over a 2 piece.

Think of it as two separate jobs where the pan replacement is first, then mini tub second. Once the pan is welded in, then tackle the mini-tubs. To save some effort, the seams where the mini-tub will need to be removed anyways just tack in place, then remove the section when cutting out for mini-tubs.

I use a spot weld cutter to remove factory welds, remove old panels, and straighten out the flanges where the spot welds were for a nice fit up when the new panel goes in.

Agree with @Adam, DO NOT overlap panels where factory did not overlap panels. Make the nicest butt weld you can and grind top bottom of seam. Most other people don’t like it and it will always look like a repair job vs a restoration, but a butt seam is much more work overall and requires more skill to accomplish nicely.

With the 2 piece pan I would tackle one side first, check reference points, then tack in place. Fit second side, check reference points, then tack in place. Re-check reference points and start welding up seams.

I find 2 piece pans are easier to install and adjust if needed (some do need it), than the one piece due to the size and the repro stamping does not always fit as is. If the tail pan needed replacement and was removed I would consider a 1 piece install over a 2 piece.

Think of it as two separate jobs where the pan replacement is first, then mini tub second. Once the pan is welded in, then tackle the mini-tubs. To save some effort, the seams where the mini-tub will need to be removed anyways just tack in place, then remove the section when cutting out for mini-tubs.

As far as mini-tubs goes, if you have the funds go with the kit or save for it, hands down, much easier to install if this is the first time.

Without the kit, if you slit the wheel house and add in a strip, the challenge is the transitions of the patch.

The area you have planned with the tape, the panel is sloping downward toward the trunk pan. The top of the wheel well is NOT horizontal, so after you slit the wheel house and move the inner wheel house in-board the new metal strip has weird transitions on the left & right of the strip. The fix is you would need to stretch out the wheel house with a hammer & dolly so that the shape of the metal transitions nicely from wheel house to patch back to wheel house again.

In the end, slitting & adding a strip requires much more skill to achieve good results since it requires metal shaping experience and a lot more grinding (since you have top and bottom of weld, times 2 weld joints, driver & passenger side)

Hope this helps in making a decision for your plan, best of luck & post photos of your progress

Without the kit, if you slit the wheel house and add in a strip, the challenge is the transitions of the patch.

The area you have planned with the tape, the panel is sloping downward toward the trunk pan. The top of the wheel well is NOT horizontal, so after you slit the wheel house and move the inner wheel house in-board the new metal strip has weird transitions on the left & right of the strip. The fix is you would need to stretch out the wheel house with a hammer & dolly so that the shape of the metal transitions nicely from wheel house to patch back to wheel house again.

In the end, slitting & adding a strip requires much more skill to achieve good results since it requires metal shaping experience and a lot more grinding (since you have top and bottom of weld, times 2 weld joints, driver & passenger side)

Hope this helps in making a decision for your plan, best of luck & post photos of your progress

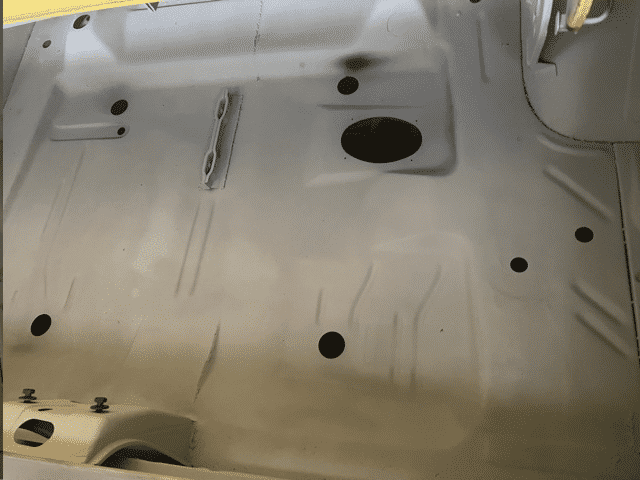

I was able to work on the car a little this weekend. I cut out all the rust but after looking at it I will probably cut out everything up to the shock tower access holes. I feel it will be too much extra work trying to butt weld up to the point I cut out. Any recommendations is highly appreciated. I still need to get the trunk flanges off of the wheel tubs. I need to remove the wheels so I can access the spot welds on the inside. Only issue is I don't have the wheel locks so I need to get some "special sockets" to get that done.

Why not cut the pan forward of the shock mounts where the factory spot welds are to avoid butt welding on the forward seam?

Along the rear seam same deal, cut the trunk pan back to tail panel where factory spot welds are to avoid butt welding at the rear area?

Wheel locks, could a 12pt socket be hammered on to the wheel lock to remove them without a special socket?

Along the rear seam same deal, cut the trunk pan back to tail panel where factory spot welds are to avoid butt welding at the rear area?

Wheel locks, could a 12pt socket be hammered on to the wheel lock to remove them without a special socket?

Similar threads

- Replies

- 7

- Views

- 431